|

|

|

|

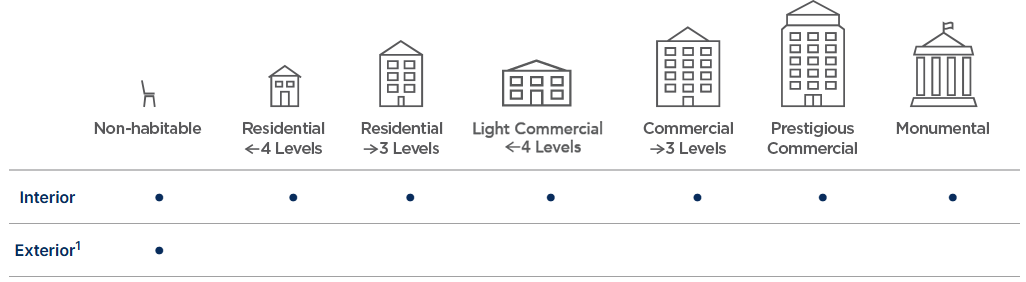

It is ideal for use:

Surreal Effects is only suitable for coastal environments >500m from the high tide line.

All Dulux Powder products are NOT suitable in strongly acidic or caustic environments so the the pH must be between 5 and 9.

Steel substrates shall be prepared as follows:

1. Wash and degrease all surfaces to be coated in accordance with AS1627.1 with a free-rinsing, neutral/alkaline detergent, in strict accordance with the manufacturer’s written instructions and all safety warnings.

2. Wash with fresh potable water and ensure that all soluble salts are removed. Testing if required can be done in accordance with AS 3894.6 for the determination of residual contaminants.

3. Grind all sharp edges with a power tool to a minimum radius of 2mm.

4. Hand or power tool clean welds to AS1627.2 to remove roughness. Remove filings, preferably by vacuum.

5. Abrasive blast clean all steel surfaces to be powder coated in accordance with AS 1627.4 to the visual cleanliness standard of SA 2.5. Use a medium that will generate a surface profile of 35 to 65 microns. In situations where it is not possible to prepare your item on all surfaces as described above, for long term protection against corrosion it is strongly recommended whenever possible, that an alternative substrate such as aluminium be considered. Failure to suitably prepare your steel substrate may void your Steel Shield™ warranty.

6. The steel must be coated within 4 hours of blasting and stored in an area which is clean and dry. Dulux Accredited Powder Coaters must comply with the metal pre-treatment guidelines set out in the Accredited Steel Shield™ Manual.

Metal Temperature:

210° : 4 mins minimum

200° : 5 mins minimum

180° : 8 mins minimum

Use the following table to help identify where Surreal Effects can be applied on aluminium projects. Refer to the conditions information to determine the environment that your project will be exposed to.

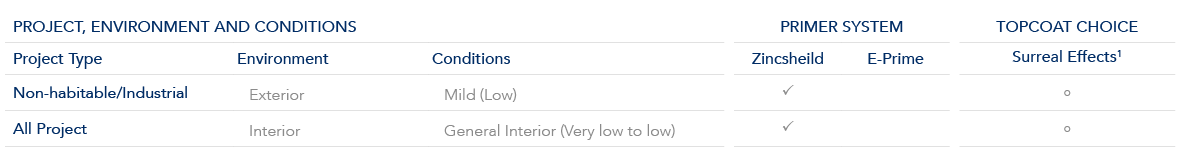

Use the following table to help identify where Surreal Effects can be applied on steel projects. Refer to the conditions information to determine the environment that your project will be exposed to.

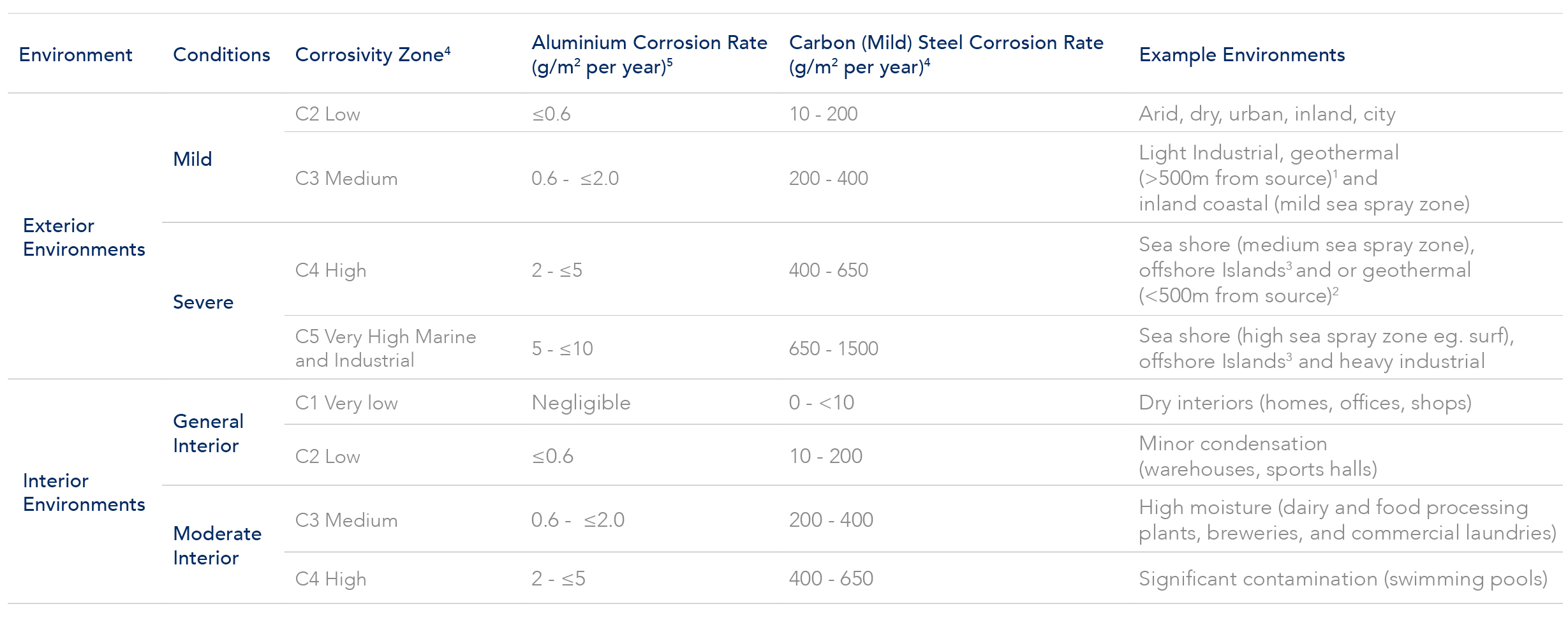

Use the following table which references AS2312.1, SNZTS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 0800 800 975

Colours displayed should be used as a guide for your colour selection.

Always confirm your colour choice with a production line prepared swatch for final colour approval.

* Only Dulux Accredited and Dulux Prime Accredited Powder Coaters are able to issue our Dulux Alumi Shield™ and Steel Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

The Surreal Effects range is a collection of functional and decorative textures and ripple effect finishes, designed to conceal surface imperfections, delivered with tough polyester thermosetting powder.

Flat

90133641

Gloss

9012315Z

Gloss

9013280Z

Gloss

9012015Z

Gloss

9017347Z

Gloss

9017041Z

Gloss

90185184

Gloss

9016552Z

Flat

9019263F

Gloss

9019258Z