![]()

It’s ideal for use:

Grey Primer/E-Prime™ can be used as a primer over a variety of substrates including steel and aluminium but is especially suited to aluminium castings, hot dipped galvanised or other porous metals.

Ideal for warranty grade application over:

E-Prime can also be used on the following metals but these are not warranted:

E-Prime is not suitable for exterior exposure so a polyester topcoat is required. It contains an epoxy component which will chalk on exterior exposure.

Modified epoxy based powder primer

Grey Primer/E-Prime

Solid look

Matt

Interior and exterior use as a basecoat only

Steel substrates shall be prepared as follows:

1. Wash and degrease all surfaces to be coated in accordance with AS1627.1 with a free-rinsing, alkaline detergent, in strict accordance with the manufacturer’s written instructions and all safety warnings.

2. Wash with fresh potable water and ensure that all soluble salts are removed in accordance with AS 3894.6 methods A&D.

3. Grind all sharp edges with a power tool to a minimum radius of 2mm.

4. Power tool clean welds to AS1627.2 Class 2 to remove roughness. Remove filings, preferably by vacuum or compressed air. 5. Abrasive blast clean all steel surfaces to be painted in accordance with AS1627.4 to visual standard AS1627.9 Class 2.5 (equivalent to ISO8501-1, Sa 2.5: Very Thorough Blast-Cleaning). Use a medium that will generate a surface profile of 35 to 65 microns (as tested to AS3894.

5 Method A.) In situations where it is not possible to prepare your item on all surfaces as described above, for long term protection against corrosion it is strongly recommended whenever possible, that an alternative substrate such as, aluminium be considered.

6. The steel to be stored in an area which is clean and dry

7. The steel must be coated within 4 hours of blasting.

Electrostatic Spray

210 for 8 mins minimum

200 for 10 mins minimum

190 for 15 mins minimum

When applying subsequent coats partially cure for 3-5 minutes at 120-150°C metal temperature. This partial cure is referred to as a green cure. Refer to the E-Prime Data Sheet for full details.

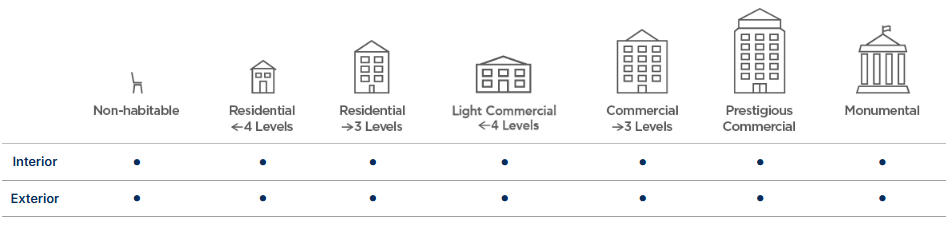

Project Suitability – Perforated and Expanded Aluminium

Dulux recommend a Alumi Shield™ warranty system for both interior and exterior usage on perforated and expanded aluminium. The use of a E-prime powder primer over suitably pretreated architectural grade aluminium is mandatory in conditions of high corrosivity below a recommended top coat. Although not mandatory in other areas, the use of E-prime is also recommended for enhanced corrosion protection on perforated and expanded aluminium.

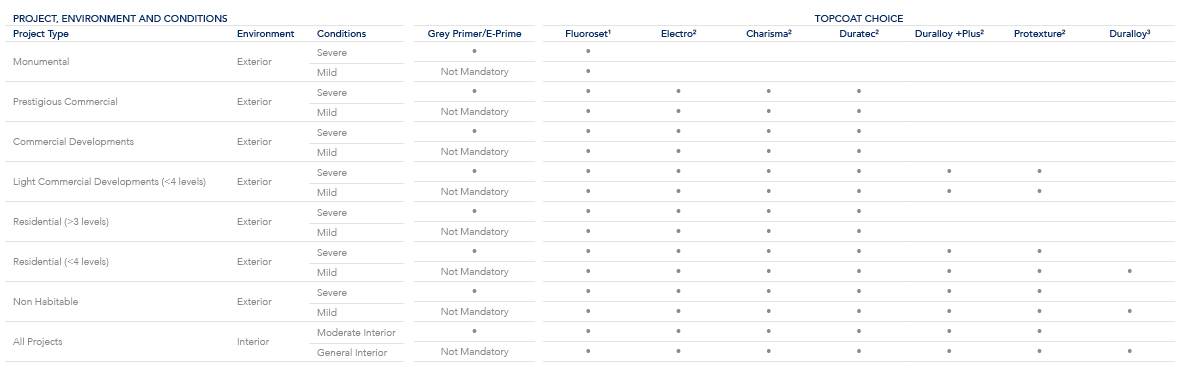

Use the following table to help identify where Fluoroset can be applied on aluminium projects, the system required and the Dulux Alumi Shield™ warranty level available. Refer to the conditions information to determine the environment that your project will be exposed to.

Project Suitability – Steel

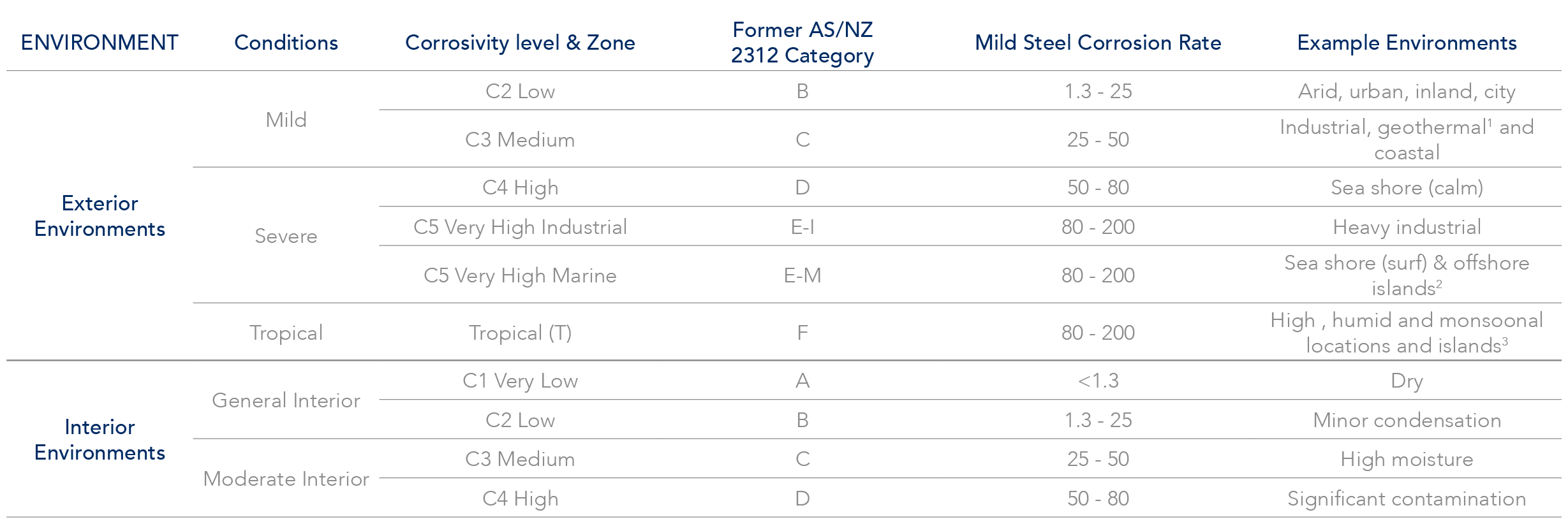

Conditions – Alumi and Steel

5. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium are determined by the following standard:

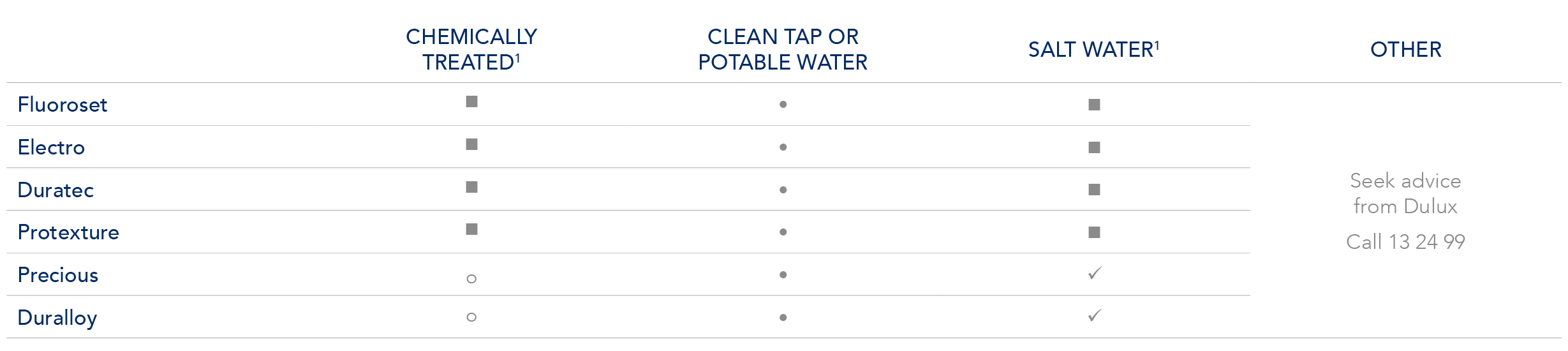

Interior and Exterior environments close to liquids other than the sea

Grey Primer/E-Prime suitability for environments close to liquids other than the sea is dependent on the top coat choice.

Please refer to the guidance below for:

1. Aggressive liquids such as Chemically Treated liquids and Salt Water must be cleaner off immediately as per the Dulux Care and Maintenance guide.

Please note chemically treated water includes antimicrobial treatments, e.g. in pools, anti-corrosive chemicals, and soapy water in bathrooms and showers.

■ Where indicated Alumi Shield and Steel Shield warranties are available on areas >than 1m from the liquid.

✓ Where indicated Alumi Shield and Steel Shield warranties are available on areas >than 2m from the liquid (ie outside the splash zone).

○ Where indicated Alumi Shield and Steel Shield warranties are available on areas >1m from the liquid on interior applications and >2m on exterior applications

● Where indicated Alumi Shield and Steel Shield warranties are available any distance from the liquid.

Alumi Shield and Steel Shield warranties are only available when applied by a Dulux Accredited Powder Coater to the warranty specification on recommended project types and conditions.

All Dulux powder products are NOT suitable in strongly acidic or caustic environments so the pH must be between 5 and 9.

Alumi Shield and Steel Shield warranties are not available if the powder coating is immersed in any liquid.

Advice Line

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 13 24 99