|

|

It is ideal for use:

Armourspray® powder coatings have a multitude of uses over various substrates including steel and aluminium.

Examples include: platform signage and train components, outdoor street furniture, bus shelters, security lockers, road infrastructure and general signage, roller shutter doors, transformers, and furniture for industry and schools.

Ideal for warranty grade application over:

Armourspray® can also be used on the following but is not warranted:

Armourspray®

Superior: 5

Excellent: 4

Very good: 3

Good: 2

OK: 1

Not Applicable: 0

Description of measures:

Visit the contact us page to get in touch.

The pre-treatment process must be capable of meeting the performance outputs as described in AS3715 and AAMA 2603 Compliance to appropriate process parameters is essential in ensuring compliance to etch, conversion coating weights (time/concentration) and conductivity of the final rinse.

The etch process is a very important stage of pre-treatment and close consultation with your pre-treatment supplier is strongly recommended to ensure optimum adhesion & corrosion resistance is obtained. As an approximate guide:

This is the next pre-treatment process for aluminium to ensure that it is suitably prepared for coating.

Final rinse is to ensure optimum surface preparation prior to coating.

Care should be taken with handling to ensure health and safety measures are met and that the substrate is not contaminated.

If your site uses a dry off oven to assist in the pre-treatment process, consult your pre-treatment supplier for advice, but generally;

The pre-treatment process must be capable of meeting the performance outputs as described in AS3715 and AAMA-2604

Steel substrates shall be prepared as follows:

Electrostatic Spray

Metal Temperature:

210° for 10 minutes

200° for 12 minutes

195° for 15 minutes

1. Carefully remove any loose surface deposits with a wet sponge by gently rubbing.

2. Clean by gently rubbing the surface with a soft brush (non-abrasive) and a dilute solution of a mild detergent, e.g. pH-neutral liquid hand or dishwashing detergent in warm water to remove dust, salt and other deposits. For stubborn stains use only recommended solvents on the affected area, e.g. Isopropyl alcohol (IPA) or methylated spirits and rinse off with clean water. Do not use other aggressive solvents.

3. Rinse the surfaces with clean fresh water after cleaning to remove all residues.

If the steps outlined above do not remove graffiti from affected areas, follow these steps:

4. Either spray graffiti remover GuardIt® Soy Safe Sensitive or apply GuardIt® Soy Allstone Gel using a soft brush to the affected surface area and leave for at least 5 minutes. Follow the safety instructions listed on the GuardIt® product label. Visit guarditsolutions.com.au for product availability.

5. Using a clean damp soft cloth gently wipe the surface and rinse with clean fresh water to remove all residue.

6. If graffiti is still visible repeat steps 4 and 5 again.

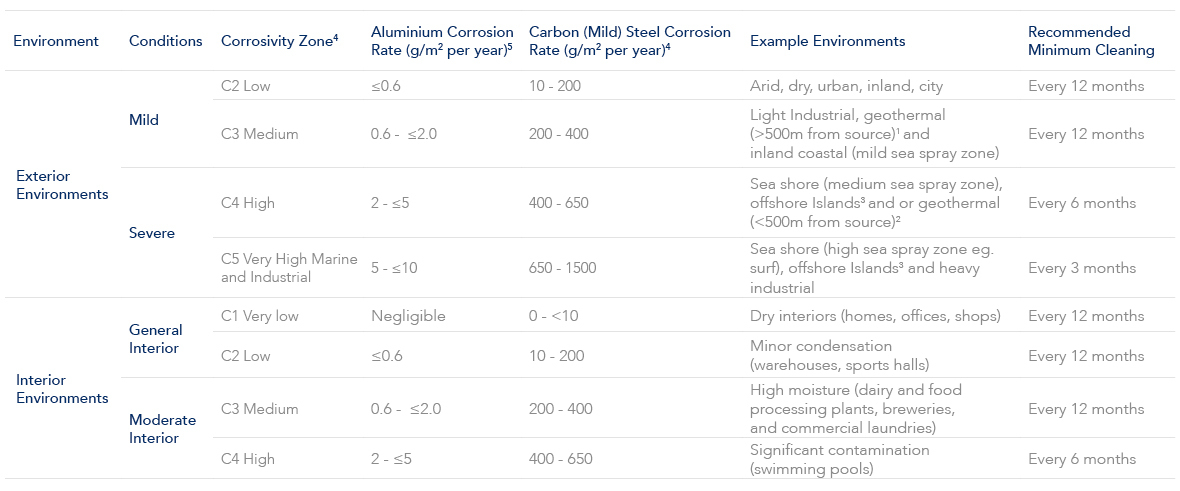

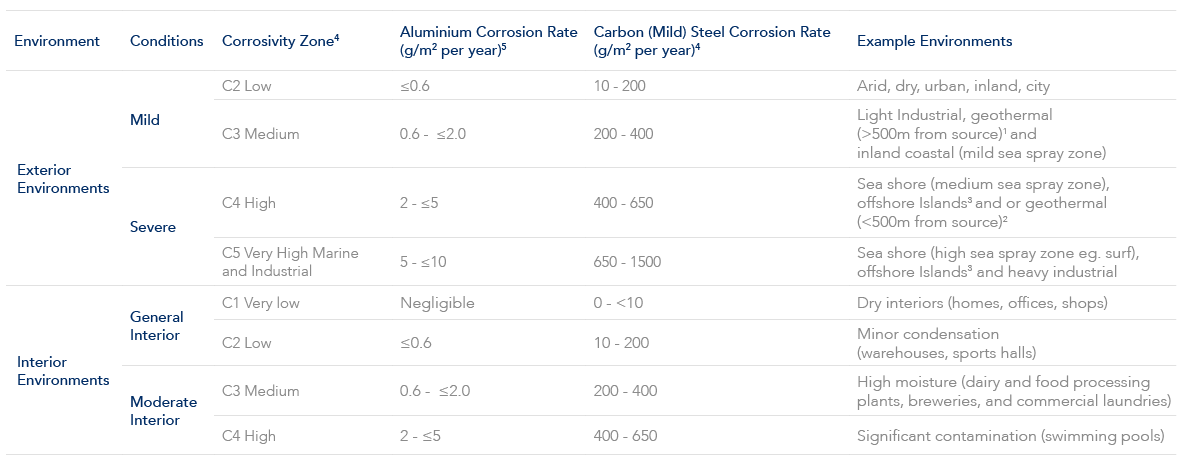

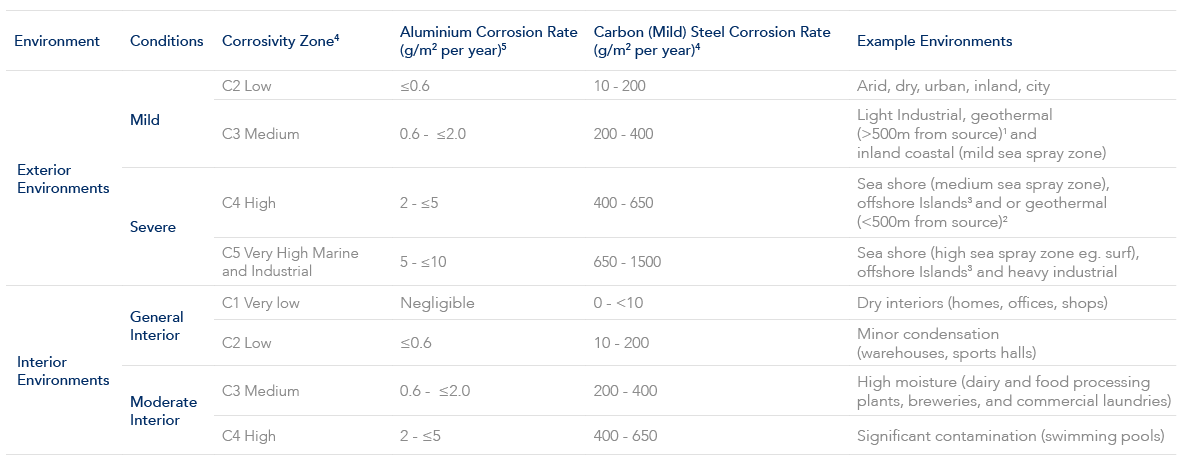

The table references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories.

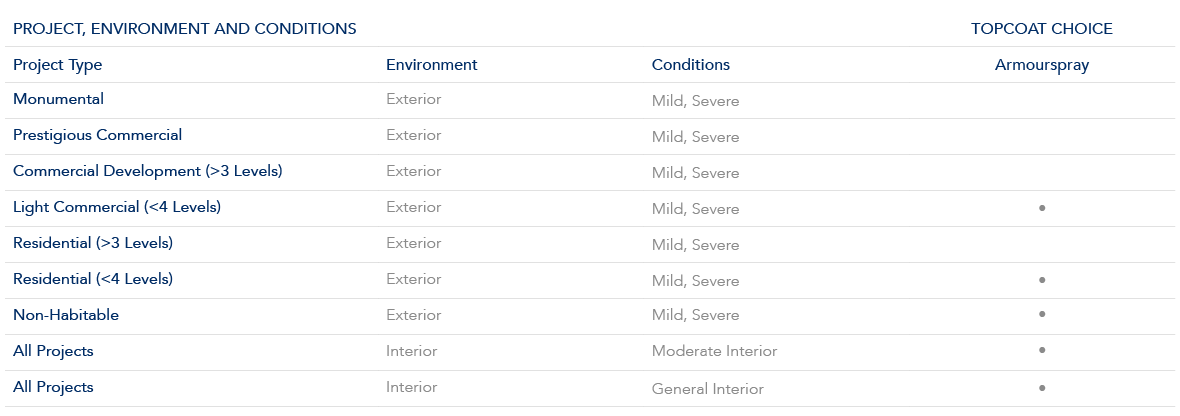

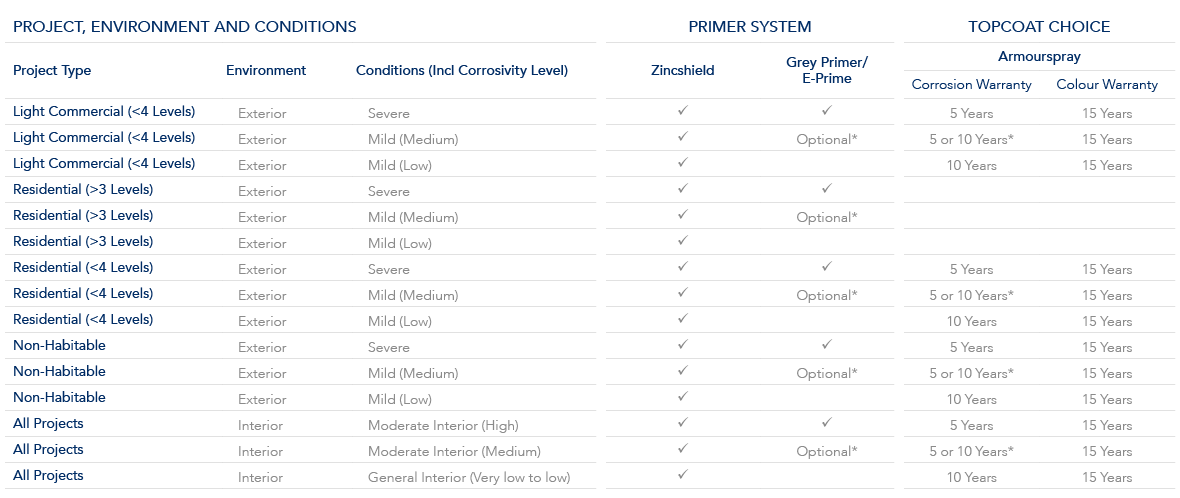

Use the tables below to determine the appropriate the product choice you have to gain a Alumi Shield™ warranty by determining the environment that your project will be exposed to. Use this together with the Dulux Macroclimate Corrosivity Corrosivity Zone Maps of New Zealand Guide, available here, or the online Dulux SpecMap tool, available here.

Use the tables below to determine the appropriate the product choice you have to gain a Steel Shield™ warranty by determining the environment that your project will be exposed to. Use this together with the Dulux Macroclimate Corrosivity Corrosivity Zone Maps of New Zealand Guide, available here, or the online Dulux SpecMap tool, available here.

Armourspray is only suitable for coastal environments > 10m from the high tide line. All Dulux powder products are NOT suitable in strongly acidic environments so the pH must be between 5 and 9. * In Mild (Medium) exterior environments and Moderate (Medium) interior environments, a 10 year corrosion warranty is available with a Zincshield, Grey Primer/E-Prime and the indicated top coat system. Without Grey Primer/E-Prime a 5 Year corrosion warranty is available.

Please refer to ‘Interior and exterior environments close to liquids other than coastal, river and lake salt water environments’ for warranty implications in such environments.Use the following table which references AS 2312.1, SNZ TS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories. To pinpoint your projects corrosivity zone this table should be used together with the Dulux Macroclimate Corrosivity Zone Maps of New Zealand Guide, available here, or Dulux SpecMap tool available here.

Please refer to the guidance below for:

Advice Line

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

Call 0800 800 975

Colours displayed should be used as a guide for your colour selection.

Always confirm your colour choice with a production line prepared swatch for final colour approval.

* Only Dulux Accredited Powder Coaters are able to issue our Dulux Alumi Shield™ and Steel Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

Armourspray® is a range of solid, pearlescent and clear finishes with high chemical resistance allowing the removal of most forms of graffiti, delivered with warranty grade* advanced highly durable polyurethane thermosetting powder.

Matt

9121030M

Gloss

9121030G

Gloss

91296914

Satin

91K7970S

Satin

9129024S